Transformation story of E China's Datang subdistrict, socks capital of the world

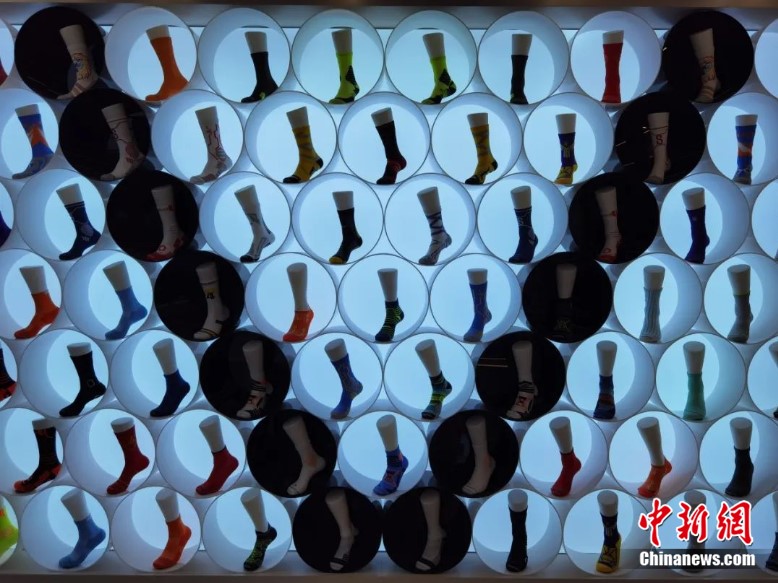

Photo shows sports socks produced in Datang subdistrict of Zhuji city, east China's Zhejiang Province. Datang subdistrict is the largest hosiery production base in the world. (Photo/Datang subdistrict)

Datang subdistrict in Zhuji city, east China's Zhejiang Province, the largest hosiery production base in the world, has undergone a significant evolution and transformation over the past decades, shifting from a nondescript small town to a high-tech hub of hosiery products.

With a population of just 76,000, Datang subdistrict produces over 20 billion pairs of socks per year - equivalent to around 2.5 pairs per person worldwide. Because of this staggering output, Datang subdistrict is referred to as "the socks capital of the world,” with around 70 percent of China's and a third of the global socks production coming from the subdistrict.

The hosiery manufacturing industry of Datang subdistrict sprouted in the late 1970s and first took off in the mid-1980s, when 70 percent of the local residents started weaving socks at home as a sideline.

Datang's first textile market opened in 1991. The following year, the market had 397 stalls selling raw materials and 1,515 finished product vendors, and saw its annual trade volume reach 610 million yuan ($84.93 million).

International orders came pouring in since 2000, when the extraordinary efficiency and capacity of local hosiery companies deeply impressed a foreign merchant. Since then, Datang has seen over a billion pairs of hosiery products exported annually worldwide as its reputation as "the socks capital of the world" has spread rapidly.

In 2002, the third-generation textile market of the subdistrict opened, with its annual turnover soon surpassing 10 billion yuan.

However, when the annual hosiery output of the local manufacturers exceeded 25.8 billion pairs in 2014, many manufacturers that earned a living by supplying hosiery products to other companies on an OEM basis got stuck in competing on price and churning out socks for pennies of profit due to a glut in low-margin production.

The solution has been upgrading and transformation. By adopting modern and intelligent facilities, including integrated hosiery knitting machines and smart factory network management systems, hosiery factories in Datang subdistrict have cut costs and improved the quality of their products over these years.

Today, production schedules and equipment monitoring are handled by smart systems based on real-time data instead of manual oversight, and digital technologies have made it possible to match inventory to orders, avoiding delays.

"I put information on the order for a batch of socks into the computer, and it would tell me if I have enough raw materials in stock, and which material I should replenish the stock with," said Dai Tiejiang, executive of a hosiery company in Datang subdistrict.

By leveraging innovation, branding, and e-commerce, local hosiery companies have opened up prospects for a larger market.

"In the past, people wore socks to keep their feet warm. Now, socks represent an important part of fashion. Hosiery companies should lead the fashion trend," said Wu Guangshi, general manager of a local hosiery company.

According to Wu, his company invests over a million yuan annually in product design. At the beginning of last year, Wu's company moved beyond the limitations of its existing products, and strategically positioned new offerings to meet young people's diverse needs, he said.

These new products have continued to gain traction in the market, and are expected to bring the company's annual sales to 80 million yuan this year, a 60-percent increase over the previous year, Wu noted.

China's burgeoning e-commerce sector has further boosted the business of hosiery manufacturers in Datang subdistrict.

The complete hosiery industry chain of Datang subdistrict has attracted a good number of e-commerce companies in the industry, multi-channel networks, and companies specializing in livestreams to the locality. So far, more than 3,000 e-commerce companies of various types operate here.

Last year, more than five billion yuan worth of e-commerce orders were completed in Datang subdistrict, as shown by data from the Zhuji bureau of economy and information technology.

Thanks to upgrading and transformation, Datang subdistrict has successfully transformed from simply producing to innovating hosiery products. Although its overall output has subsided, the hosiery production base's total output value has quadrupled over 20 years.

|

Photos

Related Stories

Copyright © 2023 People's Daily Online. All Rights Reserved.