MORAINE, United States, Sept. 23 -- "We are excited to be here because it's an opportunity to start the very beginning with a new company," said Timi Jernigan, an Ohio resident who is happy about his new career at a Chinese-invested plant in the Midwestern U.S. state.

Without a stable job for years, Jernigan, an experienced worker in the automotive industry, became in January one of the first 50 locals in Dayton hired by Fuyao Glass America Inc., a filiale of China's leading manufacturer of automotive glass, Fuyao Group.

Fuyao has invested more than 360 million U.S. dollars to build an automobile glass factory in Moraine, south of Dayton, which is expected to create more than 1,500 jobs for the local people, purchasing a 450,000-square-meter facility from the former General Motors (GM) Truck Assembly in May 2014.

The inflow of the Chinese investment has rekindled hopes for thousands of local residents, who lost their jobs in 2008 when GM shut down one of its facilities in Dayton, the fourth largest metropolitan region in Ohio.

Jernigan, in his 40s, has been re-employed as an automotive specialist at the Chinese plant, where he works 40 hours a week with a lucrative wage package and standard benefits, including health insurance and a retirement plan.

"Being a lifelong resident of this area, it just feels good that you (Fuyao) take a chance on us to help make your products and make (it) successful here in our country," Jernigan said of his new job in an interview with Xinhua.

Part of his responsibility is to ensure that the equipment in the tempering process is supplied with adequate energy, power and water and other utilities.

Not until early this year did Jernigan think of taking up a job at a Chinese factory in Dayton, a place known as the GM town, where generations of locals have worked at the facilities of the U.S. auto giant.

Jernigan has got along well with his Chinese co-workers, who were dispatched from Fuyao's factories in China to the Moraine facility to train their American counterparts.

"We like working with our Chinese colleagues, we learn a lot," Jernigan grinned, adding that "Chinese workers are hard-working, but they are (also) fun to be around."

In a Chinese company, "they encourage inclusion. They include us in decision-making even at lower level, (and) they rely on us for our experience," Jernigan told Xinhua.

Comparing his experience at the Chinese plant with his previous one at the GM facility, he said, "They let us do our test, and they trust us to do our test. But in an American company, you have to build your way up to gain that trust."

With language and cultural barriers, it is not easy for the U.S. employees to team with partners from a totally different country, but they are trying to overcome the difficulties in daily communication with their Chinese workmates.

"Americans and Chinese have different approaches and different understanding of priorities," said John Gauthier, president of Fuyao Glass America Inc. "But we still have basically the same job to do. We've got to build the factory and we have to get up running."

Jernigan is witnessing the growth of the Chinese auto plant, which is currently renovating the 140,000-square meter building in the Moraine facility and testing the equipment installed this summer.

Seven months ago, the facility was empty and left with big pits, where GM moved its equipment away. But now, it has four complete OEM glass production lines and one after-market glass line installed, with more than 200 employees at work.

"When I first walked into the plant, it was open. You can walk in the doors and look around every wall and you can see all the walls. Now you come in (to see) so much machinery in such a short period of time. That's been the biggest surprise as how quickly everything has come up," said Johnny Withrow, an operator at the lamination process, an important procedure for making automobile windshields.

According to the plant's schedule, the Moraine facility is going to start mass production in October.

Robert Semons, another former GM employee and now a Fuyao worker, also hailed the investment, thinking it worth starting a job at the new Chinese plant.

"Most (of) the jobs I had since GM was closed here were those I had to drive almost 60-80 miles (97-129 km) a day, and the pay wasn't as good," said Semons, who started to attend Fuyao introduction sessions at a local college when the company set foot in Moraine.

The Fuyao facility, the largest Chinese investment project in the Dayton region, has been widely hailed as a silver lining for the local community, as the closure of the GM plant in 2008 had dealt a heavy blow to the area, which at the same time was suffering from the loss of Delphi's auto parts manufacturing presence.

In a bid to secure the investment, the Moraine municipal government promised to give back "future revenues" to Fuyao if the Chinese company meets certain requirements such as job creation, employee training and equipment purchase, said Dave Burrows, who was vice president of the Dayton Development Coalition, a local investment promotion agency that helped secure the Fuyao investment. He now works as vice president of Fuyao Glass America Inc.

It's hard to estimate the company's impact on the local economy, as the plant has been just started up, but "we've already seen some significant results," Burrows told Xinhua.

The equipment in the plant, such as the furnace, is made by Glass Tech, a U.S. company just two hours' drive from Moraine, Burrows said, adding that Fuyao has spent a lot of money buying equipment from this company.

"Between 2024 and 2034, I see this region as a heavily Chinese-invested area. In 20 years, you are going to see billions of dollars of imports and exports and billions of dollars of revenues for companies, Chinese and American," said Burrows, noting that both sides "are benefiting from this investment" made in 2014.

The 360 million-dollar direct investment from Fuyao "certainly has significant multiplier (for the local economy)," said Kristi Tanner, senior managing director for JobsOhio, a direct investment promotion agency in the state.

According to Tanner, the economic impact on the local community is usually about 2.0 to 2.5 times the direct investment made in the automotive industry.

According to a latest report from the U.S. Rhodium Group, Chinese companies are now operating in 340 of 435 U.S. congressional districts, employing more than 80,000 Americans.

Chinese firms spend hundreds of millions of dollars annually on research and development activities and create linkages between the two countries that can help foster U.S. exports of goods and services.

The report predicted that the United States would receive 100 billion to 200 billion dollars of investment from China by 2020, and Chinese-funded U.S. affiliates would increase the number of full-time U.S. jobs to between 200,000 and 400,000.

The American employment outlook could be markedly brightened by a possible breakthrough in the China-U.S. Bilateral Investment Treaty talks, which has been widely anticipated to be achieved during Chinese President Xi Jinping's first state visit on Sept. 22-25 to the United States since he took office in 2013.

Construction of HK-Zhuhai-Macao Bridge enters final stage

Construction of HK-Zhuhai-Macao Bridge enters final stage Model of heavy-lift copter makes debuts at Tianjin expo

Model of heavy-lift copter makes debuts at Tianjin expo Art photos of Chinese beauty in Han Chinese clothing

Art photos of Chinese beauty in Han Chinese clothing Stunning photos of air show in China’s V-Day parade

Stunning photos of air show in China’s V-Day parade Models change clothes on street in Hangzhou

Models change clothes on street in Hangzhou Charming Chinese female soldiers

Charming Chinese female soldiers Beauty vs. muscular man

Beauty vs. muscular man World's passenger plane giants convene in Beijing aviation expo

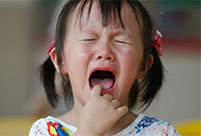

World's passenger plane giants convene in Beijing aviation expo First day in kindergarten

First day in kindergarten Military millennials

Military millennials Xi’s US visit to clear path through rhetoric

Xi’s US visit to clear path through rhetoric CASS forecasts 6.9% GDP growth for 2015

CASS forecasts 6.9% GDP growth for 2015 LGBT community looking for a happy life with kids

LGBT community looking for a happy life with kidsDay|Week