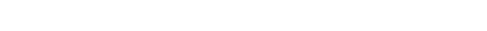

New energy vehicles from S China's Guangxi gain firmer foothold overseas

Small and nimble new energy vehicles (NEV) are a common sight on the streets of south China's Guangxi Zhuang Autonomous Region. With a length of just around 2 meters, these vehicles are half the size of a regular car, making them a convenient mode of transportation for shopping or picking up children from school.

The NEVs, developed and manufactured by Chinese automobile manufacturer SAIC-GM-Wuling (SGMW) in Liuzhou city of Guangxi, have reached overseas markets, in particular gaining popularity in the Southeast Asian market.

Photo shows small and nimble new energy vehicles developed and manufactured by Chinese automobile manufacturer SAIC-GM-Wuling in Liuzhou city, south China's Guangxi Zhuang Autonomous Region. (People's Daily Online/Fu Huazhou)

The automobile industry is an important pillar industry in Guangxi. In the new round of technological revolution and industrial transformation, the region's automotive industry is seizing opportunities, further deepening reform, and placing equal emphasis on innovation and cooperation in an effort to achieve innovative, high-quality and sustainable development.

Over the years, SGMW has been expanding its presence in the overseas market. For example, the company attended the GAIKINDO Indonesia International Auto Show in July. SGMW received widespread acclaim and was one of the highlights of the show, with local companies signing contracts to purchase the company's NEVs in bulk. Efforts like this have allowed SGMW's total export volume to reach 1 million. In 2023, the company exported 24,094 NEVs, increasing 165 percent year on year.

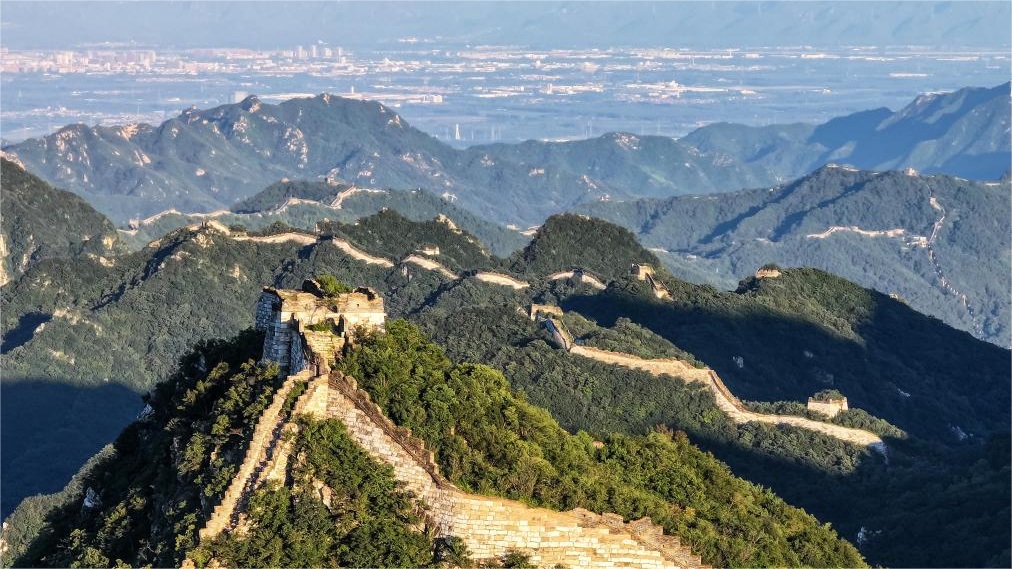

The company's rich product portfolio and strong competitiveness are a result of its intelligent manufacturing strength, which is essential for upgrading and innovating industrial capabilities.

By breaking free from the limitations of traditional assembly line models, SGMW's "smart island" factory, based on lean and modular manufacturing, has revolutionized the manufacturing process.

"The 'smart island' factory, with the production line, software and hardware independently developed and designed by us, can automatically adapt its production program to different vehicle models and configurations. This allows us to better cater to the evolving market demands of producing multiple varieties in small batches," said Xiao Xiao, SGMW's "smart island" factory's engineering director of intelligent manufacturing.

Photo shows a "smart island" factory at SAIC-GM-Wuling (SGMW) in Liuzhou, south China's Guangxi Zhuang Autonomous Region. (People's Daily Online/Lei Qijun)

SGMW embarked on the development of NEV technology in 2012. In the first 12 years, the company was able to obtain over 700 patents. However, just from 2023 to today the company managed to double the total number of patents to 1,650.

Of the 1,650 patents, most are in areas such as intelligent connected vehicles, the motor, battery and electric control system, and dual model hybrid technology.

SGMW of course isn't the only Guangxi automotive company using innovative practices and technology.

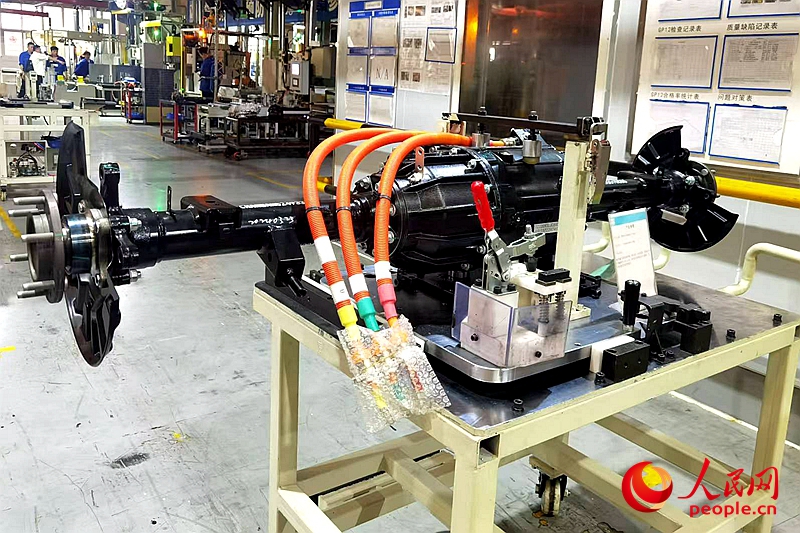

In 2023, Guangxi Automobile Group, with decades of experience in the traditional automobile industry, rose to the challenge and continuously upgraded its products, achieving breakthroughs in the production of core components for NEVs.

The development and production of the co-axial electric drive axle took the company less than a year and obtained 10 patents, making the company the first of its kind in the country to mass produce such a product for NEVs.

Photo shows a co-axial electric drive axle developed by Guangxi Automobile Group. (People's Daily Online/Qin Xin)

"Core technology has opened up overseas markets for us," said He Hongyong, general manager of the chassis division at Guangxi Automobile Group. Today, the company's automotive components have reached markets in India, Indonesia, and Vietnam.

The emergence of new quality productive forces has also injected new vitality into Guangxi's automobile industry.

In Liuzhou, an NEV industrial chain targeting the ASEAN market is rapidly being established. Additionally, the capital city of Nanning is prioritizing the development of the new energy battery industry as a core and leading industry.

Over the past two years, Nanning has emerged as a hub for the new energy battery industry. Companies like BYD have established themselves as key players.

Nanning ranked 36th on the Hurun Research Institute's 2023 list of the top 50 cities in China with the highest concentration of new energy companies.

In early August, a complete automobile production line by Dongfeng Liuzhou Motor Co., Ltd., was exported from Liuzhou to Cambodia. This marked the first time that Liuzhou exported a complete automobile production line.

Prior to this, the company had received a multitude of inquiries from clients overseas, seeking assistance in establishing complete vehicle production lines for local assembly.

Deepening reforms and expanding openness have always been the guiding principles and foundations for the development of China's automotive industry. Leveraging innovation to drive industrial transformation, Guangxi's automotive industry is rapidly growing, and the blueprint for cultivating an internationally competitive NEV industry cluster is gradually becoming a reality.

Photo shows the production workshop for commercial vehicles at Dongfeng Liuzhou Motor Co., Ltd., located in Liuzhou, south China's Guangxi Zhuang Autonomous Region. (People's Daily Online/Fu Huazhou)

Photos

Related Stories

- China's NEV industry speeds up for greener, smarter future

- NEV registrations hit record high, latest sign of robust growth despite foreign suppression

- New energy vehicles reshape the industrial ecosystem

- GM China joint venture posts strong NEV sales in H1

- China requests WTO to establish panel regarding dispute over U.S. Inflation Reduction Act

Copyright © 2024 People's Daily Online. All Rights Reserved.