Neil Brownsword: Exploring exchanges between China and the West through ceramics

The recent exhibition “Obsolescence and Renewal” by world-renowned ceramics artist, Professor Neil Brownsword at Staffordshire University examines the UK’s marginalised histories of ceramics production, reconnects contemporary audiences with native ceramics production, while also encouraging local recognition of the need to regenerate ceramics culture.

“I was born and grew up surrounded by a landscape that bears the scars of hundreds of years of industrial activity. For generations, my family has worked and continues to work in the ceramic industry, so it was perhaps inevitable that I would follow a similar path.”

Neil Brownsword. (Photo/Patrick Shead-Simmonds)

In recent years, Brownsword’s research has explored the legacy of deindustrialisation in relation to the UK’s ceramic capital, Stoke-on-Trent. He advocates for reactivating and regenerating the ceramic industry in the English city by drawing on the successful example of Jingdezhen, China’s porcelain capital.

Brownsword has been invited to the National Ceramics Culture Inheritance and Innovation Pilot Zone conference at Jingdezhen Ceramics University in October this year and looks forward to learning more about the area’s culture and history. He hopes to continue cultural exchange between the UK and China through the versatile medium of ceramics in the future.

Exploring Stoke-on-Trent’s rich ceramics history

Neil Brownsword examines clay in Stoke-on-Trent. (Photo/Patrick Shead-Simmonds)

People’s Daily Online: Stoke-on-Trent is known as the ceramics capital of the UK. Many historical ceramics factories and kilns are still preserved. Could you tell us about the region’s ceramics history?

Neil Brownsword: North Staffordshire’s history is rooted in ceramic production. By 1800 the region’s global ceramics export paralleled cities like Jingdezhen, China’s porcelain capital. One of the reasons why the ceramic industry grew out of this area is because of its geology – its surface outcrops of red burning clay and long-flame coal ideal for firing.

Bradwell Wood, the area where I grew up, remains important to the origins of industry, as it’s the site where Dutch immigrants John and David Elers established their manufactory in the 1690s. As silversmiths they transferred their knowledge of metal working to ceramic production - casting liquid clay into plaster moulds and refining objects through lathe turning. They came specifically to Bradwell to utilise its rich haematitic red clays to emulate Yixing tea wares from Southern China that were being imported into Europe at that period. However, as tea drinking increased amongst the middle classes during the early 18th century, whiter wares influenced by Chinese porcelain became the prevailing fashion.

The ceramic industry in North Staffordshire subsequently thrived with pioneer industrialists such as Josiah Wedgwood and Josiah Spode introducing cutting edge design and innovation through their production to satisfy international demand – establishing the region as a global centre of production.

People’s Daily Online: We are all aware that China’ rich ceramics culture has heavily influenced the West; for example, the Spode Factory is known for perfecting its imitation of blue and white Chinese ceramics. What research have you conducted in this area?

Neil Brownsword: Ceramic history is one which is dominated by global exchange. As commodities were traded, they became a conduit for cultural influence which in the case of ceramics subsequently spurred a wave of imitation. High fired white stonewares and porcelains made during the Tang Dynasty were shipped to the Middle East where they were highly prized and copied using the raw materials indigenous to Iraq in the 9th century. To imitate the whiteness of Chinese porcelain, potters introduced tin to low fired glazes, which they enhanced with cobalt pigment decoration, which in turn influenced early iterations of Chinese blue and white.

Marco Polo is often cited as the first European to have introduced porcelain into the West during the late 13th century. Europeans subsequently strove to re-create porcelain without access to the key ingredients - China clay and China stone, leading to the development of ‘soft-paste’ bodies. In England in the late 18th century, the Spode factory was credited with perfecting both bone China – a fine white, translucent body that consists of up to 50 percent animal bone; and blue underglaze printing to imitate expensive Chinese export porcelain.

We are currently on the site of the famous Spode factory which operated for nearly 230 years until production ceased on this site in 2008. The former Spode factory remains an important aspect of Britain’s industrial heritage which desperately needs its cultural revival. Much of the research I have conducted has tried to bring greater recognition to the sophistications of knowledge and skills that have developed and been passed down from generation to generation, which are now in danger of being lost. By placing and reimagining endangered factory skills in a contemporary art context, audiences are introduced to bodily intelligences which remain hugely overlooked.

As a professor at Staffordshire University I have been fortunate to have worked alongside Professor Tiejun Hou from Jingdezhen Ceramic University, who based his research here at the Spode Museum in 2019, to explore links between Chinese ceramics and ceramics produced in North Staffordshire. A collection of Chinese porcelain shards were discovered on the grounds of the factory, which Professor Hou examined in more depth identifying their style and origin, and potential influence on the development of early blue and white prototypes made on the factory. Its this level of collaboration and shared knowledge I want to extend through future cultural exchange as it brings mutual benefits and the uncovering of new knowledge.

People’s Daily Online: For you, what is the most fascinating aspect of Chinese ceramics?

Neil Brownsword: In terms of Chinese ceramics, I could not honestly say a favourite period as China has such a broad cultural history. I am drawn to the Tang Dynasty production, Tang Sancai, which has a wonderful combination of craft and serendipity through the fluidity of the rich coloured lead glazes. However, the most fascinating thing about Chinese ceramics is the skill, ingenuity and human knowledge, which went into their conception and production. Ceramic technology was derived through empiricism - basically through trial and error, with the tenacity to achieve perfection. The sophistications of this knowledge have been refined and passed down from generation to generation, continuing the traditions which are key to our cultural identity.

Contemporary ceramics exchange between East and West

Neil Brownsword working at his studio. (Photo/Patrick Shead-Simmonds)

People’s Daily Online: Your work has been exhibited by world-leading cultural institutions, such as the Victoria and Albert Museum, Yingge Ceramics Museum, and Korea Ceramics Foundation; you were also invited to the Fu Le International Ceramics Centre (FLICAM) in Shaanxi Province. What were some of the memorable moments during your visit to China?

Neil Brownsword: In 2008, I was invited as one of 10 British artists to create work for FLICAM’s newly established British Pavilion. Having started my career as an apprentice at the Wedgwood factory at the age of 16, returning to a space of collective endeavour was something I had wanted to do for a long time. At first, I was fascinated by documenting the skills on the factory, that were employed to make replica Tang Dynasty architectural furnishings. I eventually met with the model and mould makers– which was the area of expertise I acquired during my own apprenticeship at Wedgwood. Even though their approach remained very different to my own, it was fascinating to be an observer of their knowledge of materials and processes. Despite a language barrier we could communicate through the universal language of craft, where mutual respect was gained.

While I was at Fu Le International Ceramics Centre, I started to explore ideas surrounding the cultural copy, which underpins so much ceramic history. The origins of North Staffordshire’s ceramic industry is predominantly founded upon Chinese cultural influence, whereby functional forms and imagery were imitated, adapted and assimilated to create a new tradition. During the late 17th and 18th century, when very few Westerners had travelled to and experienced China first hand, literary accounts, images and commodities were the only means of cultural contact. The mix of reality and fantasy that ensued in early examples of Staffordshire Chinoiserie remain a continual point of fascination. Yet much of these copies lack the sophistications of material knowledge and craft evident within their Chinese points of reference. To cite this history of the ‘unfaithful copy’, I started to imitate historic replicas being made at the Fu Le factory, but to hinder my own skills I modelled these in the negative from large blocks of clay. These were subsequently filled with plaster to capture the odd spatial perspective that derived from the process and later transferred into clay.

People’s Daily Online: In 2016, you visited Nanjing University of the Arts. How did you encourage the students there to approach craft in a new way?

Neil Brownsword: This was my first visit to an educational institution in China. I was there for two and a half weeks and loved every minute of it as the students were highly motivated and eager to learn. Although they were on the whole very competent as makers, they tended to lack risk taking and often followed the style of their professors. So, I wanted to introduce a project which invited curiosity without being concerned with a final outcome. By revisiting my own history, I took the early empiricism of 18th century Staffordshire potters and their attempts to recreate Chinese porcelain as a starting point. Without understanding the ingredients necessary to make true porcelain, white firing clays and other materials such as crushed glass and alabaster were combined to create new ceramic bodies. By returning to the raw materials that constitute ceramics and playfully combining this without the structure of prior knowledge dictating what was right or wrong. The students were very willing to experiment and find a new way of working, and embrace failure as an essential part of the creative journey, which they really valued and learned from also.

Learning from Jingdezhen to regenerate the ceramics industry

People’s Daily Online: How has globalisation impacted ceramics production in Stoke-on-Trent?

Neil Brownsword: During the last three decades, global economics have led to significant transitions that have impacted production in Stoke-on-Trent. Renowned historic manufactories in the region decided to outsource their ceramic production to parts of East Asia where energy and direct labour were a fraction of the cost compared to the UK. This has led to a significant decline, leading to factory closure and a break within the tradition of skills being passed on from generation to generation. Jingdezhen also experienced a period of deindustrialisation in the mid-1990s, however the the city and its ceramic artisans have been able to reinvent themselves.

Stoke-on-Trent can learn from places like Jingdezhen in China, which has similar traditions, knowledge base and tactile skills. I believe, just like what Jingdezhen has achieved, building something like a centre of excellence for ceramics in the region would create a space where traditional knowledge could be passed on and applied in new ways. This could alongside the development of new technology, regenerate production, skills and refresh the ceramics industry in Stoke-on-Trent. It’s about thinking through the past for the future.

People’s Daily Online: What are you looking forward to the most during your visit to Jingdezhen?

Neil Brownsword: I have been invited to Jingdezhen Ceramic University in October to participate in a conference on cultural heritage. I am fascinated to see how both new and traditional technologies are used in this ceramic city. I hear that everything, even lampposts are made of ceramic, and they celebrate the city’s ceramic heritage everywhere you turn. I feel this is what Stoke-on-Trent needs. Being exposed to history and material culture in Jingdezhen will be beneficial in making me think in new ways when I am back in the UK. Cultural exchange is instrumental to what I do as an artist and a researcher. It allows me to experience other situations where possibilities and limitations lead to new research that will enable me think differently and more creatively.

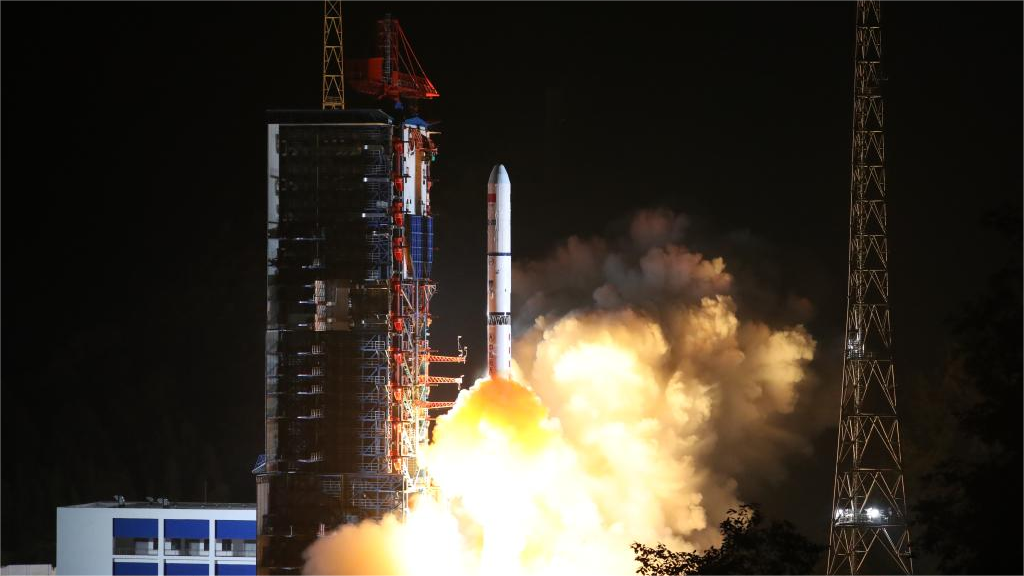

Photos

Related Stories

- Innovation breathes new life into Jingdezhen ceramics

- Contemporary ceramics exhibition kicks off at 19th China (Shenzhen) International Cultural Industries Fair

- Handmade porcelain flowers showcase the art of ceramics

- China inaugurates world's first "gene bank" of ancient ceramics

- World’s first “gene bank” for ancient ceramics to be built in China’s “porcelain capital” of Jingdezhen

- China’s first “gene bank” for ancient ceramics inaugurated in Jingdezhen

Copyright © 2023 People's Daily Online. All Rights Reserved.