Fujian artisan revives traditional bow and arrow crafting in SE China

Zhang Zhaoyu straightens an arrow.

Zhang Zhaoyu makes an arrow.

Zhang Zhaoyu fletches an arrow.

Zhang Zhaoyu paints an arrow.

Photo shows arrows made by Zhang Zhaoyu.

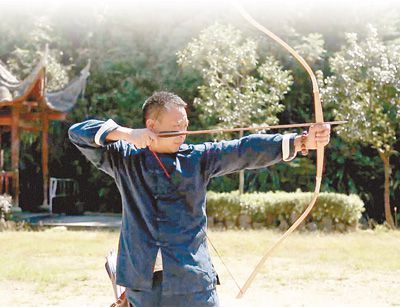

Zhang Zhaoyu tries a bow and arrow. (Photo courtesy of the interviewee)

Bow and arrow crafting, a traditional art in Pingnan county, Ningde city, southeast China's Fujian Province, thrives amidst the region's vast bamboo forests. Local artisans have long committed themselves to reviving this craft and reenergizing the sport of archery.

Zhang Zhaoyu, 52, an inheritor of bow and arrow crafting techniques in Pingnan, has worked tirelessly to restore this traditional craft and promote the sport of archery.

Inside his workshop, Zhang can be seen crafting a wooden bow from bamboo, meticulously scraping the bamboo board until it gains resilience.

Winter is the ideal time for Zhang to gather his bamboo, selecting plants that have grown for four to five years in the mountains. According to Zhang, bamboo harvested in winter has lower water and sugar content, making it less susceptible to pests and optimal for bow creation.

The process begins by heating a bamboo cane over a fire. Zhang then slices the bamboo into a board, approximately 3.33 centimeters wide. After reducing the thickness of the bamboo board, he uses the remaining piece as the main body of the bow.

"The bow is made by joining two pieces of bamboo boards together," said Zhang.

It's not easy to make an arrow and there are many procedures involved, according to Zhang. An arrow must be tailored to the archer's arm strength and length to function effectively, requiring a deep understanding of these attributes.

The raw material for making arrows is large-leaved bamboo. The best ones are bamboo stalks that have grown for three to five years and have a diameter of 8 to 10 millimeters.

To make an arrow, Zhang first divides a bamboo cane into sections and heats them over a fire to soften and straighten them. Zhang carefully handles the bamboo during this process to ensure it maintains resilience while becoming straight. Zhang said the most difficult part is to straighten the arrow and he usually checks an arrow five to six times to make sure it is ready for use.

Zhang started learning the craft from his uncle when he was eight.

In ancient times, people in Pingnan hunted with bows and arrows. However, the ancient craft was almost lost as traditional bows and arrows gave way to modern archery. As a result, Zhang only initially learned to create bows and arrows from a single piece of bamboo.

In 2008, Zhang learned that Xu Kaicai, former head coach of the Chinese national archery team, had launched an effort to revitalize traditional archery. Zhang reached out to him. Under Xu's mentorship, Zhang decided to restore the techniques for crafting traditional bows and arrows.

Zhang finished restoring an arrow-making technique in 2012. Compared to a normal bamboo arrow, this one was made by joining three or more bamboo strips together. It was straighter and boasted greater flight stability.

After that, Zhang dedicated over a year to creating a bow from two bamboo pieces, which proved powerful, precise, and user-friendly.

In 2016, traditional bamboo bow and arrow crafting in Pingnan was recognized as an intangible cultural heritage of Ningde city.

In August 2014, the traditional bow branch of the archery association of China was established to vigorously promote traditional archery. Today, traditional archery has gained popularity across the country.

Zhang has since established a company that produces bow and arrow manufacturing tools and mechanical equipment. The company sells about 500,000 bamboo arrows annually and provides 90 percent of the bows and arrows used in traditional archery competitions.

Photos

Related Stories

- Ocean sanitation station dedicated to removal of marine waste in SE China

- In pics: terraced fields in China's Fujian

- Tea industry brings wealth to locals in Yongtai, SE China's Fujian

- Beiqian Village attracts tourists with multi-format industry in SE China's Fujian

- Craftsmen dedicated to inheriting ancient shipbuilding culture in SE China's Fujian

Copyright © 2023 People's Daily Online. All Rights Reserved.